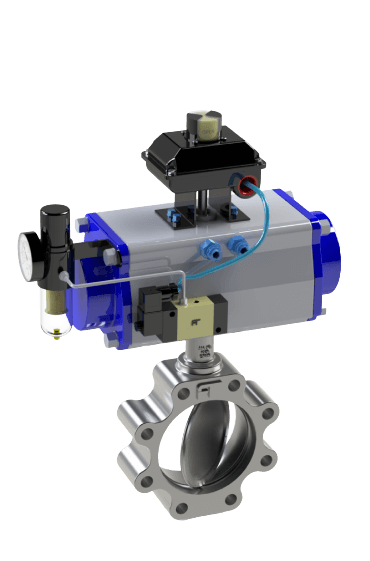

A butterfly valve is a widely used flow control device that regulates, starts, or stops fluid flow in pipelines. Its simple yet effective design consists of a disc mounted on a rotating shaft. When the valve is fully opened, the disc turns to align parallel with the flow, allowing minimal resistance. When closed, the disc rotates perpendicular to the flow, blocking the passage of fluid. This makes butterfly valves a reliable and efficient solution in many industries.

Functions of Butterfly Valves

The primary function of a butterfly valve is to control the flow of liquids, gases, or slurries in a system. The valve can perform the following key tasks:

Shut-off: It can completely stop the flow of a fluid, acting as a shut-off valve. The disc closes tightly against a seal to prevent leakage.

Regulation: These valves are often used for throttling, or regulating the flow of fluid. The position of the disc can be adjusted to control the flow rate, making these valves versatile in different applications.

Flow Isolation: In systems that require flow to be directed in a particular manner, valves are used to isolate different sections of the piping network.

Backflow Prevention: Some butterfly valves are designed to prevent backflow by closing automatically when the flow stops.

Uses of Butterfly Valves

They are widely used across various industries due to their versatility and efficiency. Common uses include:

Water and Wastewater Treatment: They control water flow in treatment plants and pipelines, particularly in larger diameter applications.

Oil and Gas: In oil and gas industries, They are used for flow isolation and regulation in pipelines carrying oil, gas, or other hydrocarbons.

Food and Beverage: These valves are utilized in processes requiring hygienic conditions, as they can be easily cleaned and maintained.

HVAC Systems: It regulate airflow in heating, ventilation, and air conditioning systems.

Chemical Processing: They are used in chemical plants to manage the flow of corrosive or hazardous substances due to their high resistance to corrosion and easy operation.

Pharmaceuticals: In the pharmaceutical industry, It help maintain purity by regulating flow in purified water and air systems.

|

| https://www.freture.com/butterfly-valves-manufacturers/single-offset-butterfly-valves/ |

Advantages of Butterfly Valves

Compact Design: One of the biggest advantages of these valves is their compact and lightweight design. This makes them ideal for systems where space is limited or where weight needs to be minimized, such as in pipelines and process industries.

Cost-Effective: They are typically more affordable than other valve types like gate valves or globe valves, especially in larger sizes. Their relatively simple design and lower material costs make them a cost-effective option.

Quick Operation: With a 90-degree turn of the handle, a butterfly valve can fully open or close, providing quick and efficient operation. This is particularly useful in applications where immediate shut-off is required.

Versatility: These valves are suitable for handling a wide range of fluids, including liquids, gases, and slurries, and they can be adapted for manual, electric, or pneumatic actuation.

Low Maintenance: Due to fewer moving parts and a simple design, this valves require less maintenance compared to other types of valves, contributing to lower operational costs over time.

Energy Efficiency: In the fully open position, the disc causes minimal obstruction to flow, leading to lower pressure drops and energy savings in fluid transport systems.

Disadvantages of Butterfly Valves

Limited Sealing: While they are effective for flow regulation, they do not always provide a perfect seal, especially in high-pressure applications. This can result in slight leakage.

Pressure Sensitivity: They may not perform well in very high-pressure systems, as the disc can become deformed, leading to compromised operation.

Disc Obstruction: Even when the valve is fully open, the disc remains in the flow path, which can cause turbulence or a slight reduction in flow efficiency, particularly in high-velocity fluids.

Not Ideal for Throttling in Some Cases: They are not always the best option for precise flow control in throttling applications. Small changes in disc position can result in significant variations in flow rate.

Butterfly Valve Specifications

When selecting a butterfly valve, various specifications must be considered depending on the application. Key specifications include:

Valve Type: They come in various types, including concentric, double-offset, and triple-offset designs. Each type has unique features to handle different pressure levels and flow conditions.

Size Range: They can be manufactured in a wide range of sizes, typically from 2 inches to over 72 inches in diameter, depending on the system's requirements.

Pressure Rating: The pressure rating of a butterfly valve is crucial. They can typically handle pressures ranging from 150 psi to over 1,000 psi, depending on the design and materials used.

Temperature Range: Butterfly valves are suitable for handling fluids at various temperatures, from cryogenic levels to high-temperature applications of up to 1,000°F or more.

Body Materials: Common body materials for butterfly valves include cast iron, stainless steel, carbon steel, and high-performance alloys. The material should be chosen based on the fluid's nature and the operating environment.

Seat Materials: The seat, which forms the seal between the valve body and the disc, is usually made from materials such as PTFE, PFA, FEP, PVDF Lined butterfly valves, depending on the application's pressure and temperature requirements.

Conclusion

Butterfly valves offer a highly efficient and cost-effective solution for controlling the flow of various fluids across many industries. Their compact design, quick operation, and versatility make them a popular choice, although they do have limitations in sealing and pressure resistance. By selecting the right type and specifications for your system, butterfly valves can provide reliable performance with minimal maintenance.